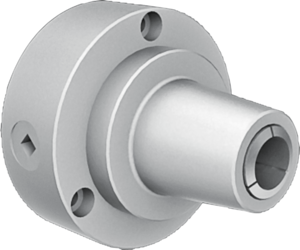

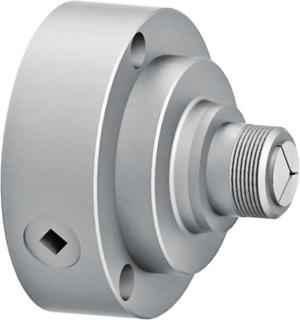

Manual collet chuck

The functional principle is similar to that of spiral chucks.

A pull or push sleeve is actuated by the radial clamping initiation via the drive pinion, which pulls or pushes the collet into the cone. The concentricity of the manual collet chuck is < 0.01 mm, depending on the type. All wear parts are inserted and hardened for maximum stability, precision and service life. This design enables us to achieve very high clamping forces and maximum accuracy.

These manual collet chucks are used on conventional and cycle-controlled lathes, milling machines, dividing heads, rotary tables, grinding machines and measuring machines. Thanks to their slim and compact design, these manual collet chucks are also ideal for 5-axis applications on dividing heads or rotary tables.

The manual collet chucks are available in various designs and sizes for the following collet types:

- Collet chucks W20 (349E) / W25 (364E) / 5C (385E, W31.75) / B32 (3713E)

- B45 (3838E) / 386E

- Expanding mandrels and bell collets W20 / W25 / B32

- Compression collets F32 (161E) / F35 (163E) / F38 (164E) / F48 (173E) / F66 (185E)

- Clamping heads size 32 / size 42 / size 52 / size 65 / size 80 / size 100

We also offer chucks directly with an adaptation (flange) to suit your lathe. We can supply you with flanges with camlock system DIN 55029 / bayonet with stud DIN 55027 / direct mounting ASA or DIN 55026.

Extract from machine manufacturers for our wedge bar chucks: Weiler, GDW, EMCO, Seiger, Colchester, ROMI, DMT Kern, UNITECH, Masturn, AVIA, HAAS, Lehmann, Nikken, Tsudakoma and others.